Basic and detail engineering

At SAR our knowledge of engineering encompasses the process and installation-related planning and processing of system components for new construction, modernisation and service projects.

We provide expert know-how in all area of process engineering and power plant technology:

- Carrying out an inventory whilst at the same time devising concrete suggestions for optimisation

- Drawing up tender documents, supervision of a full tender procedure as a neutral building consultant

- Specifications and functional specifications, feasibility studies

- Definition and administration of PPS (KKS) labels and measuring sites

- Labelling of measuring sites for process engineering systems (e.g. as per DIN 19227 or ISA)

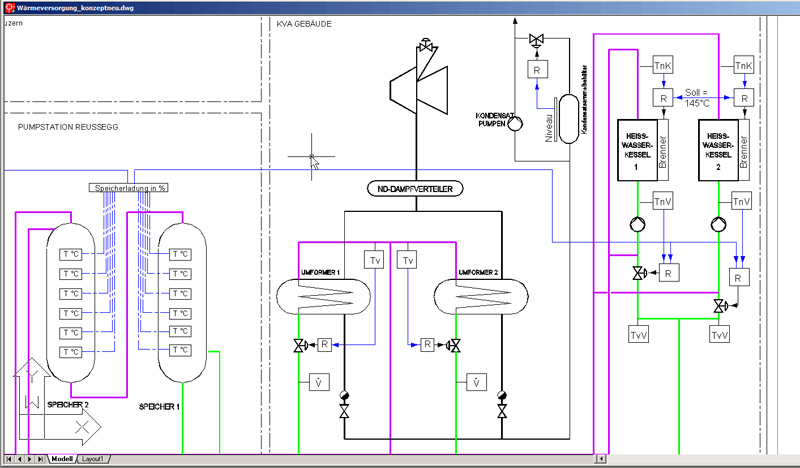

- Basic and detail engineering for process engineering systems

- Drawing up and maintenance of P&ID diagrams

- Formulation of verbal functional descriptions and system-neutral functional plans as per VGB R170C

- Electrical and process engineering inventories, as-built documentation for existing plants

- Planning and construction of emissions measurement systems as per TA-Luft or BimSchV (Federal Clean Air Act)

- Safety analyses (HAZOP, LOPA) as per IEC 61508/61511, SIL assessment of safety functions

With regard to the electrical and controlling equipment of plants, we focus on the following tasks:

- Definition of device specifications from field instruments right through to process control systems

- Development of automation and operation concepts

- Development of concepts for MV / LV and UPS plants (both for new plants and for the modernisation of existing plants)

- Detailed design of control cabinets, distribution cabinets and field distributors

- Electrical design of complete control and process control systems using the most up-to-date CAE tools

- Construction planning, cable run construction planning, track planning

- Service, maintenance and recurring inspections for MV plants

One area which is especially worth mentioning is our experience in the modernisation of old plants (retrofitting), in which we are aware that the shortest possible down time and smoothest possible restart are particularly important.

We are also very happy to dedicate ourselves to specific topics, such as control circuits which are not optimally adjusted to one another, increases in performance and throughput, ad hoc retrofitting of incorrectly dimensioned actuator technology, poorly positioned measuring equipment etc. These areas often offer considerable potential for optimisation which falls by the wayside in day-to-day operation. A neutral view of the plant by an independent specialist can identify, and thus make it possible to harness, this potential.