Combustion control system SAR-CCS

Optimal incineration results with maximum efficiency and minimum emissions

As a result of the ever stricter legal requirements regarding emissions control, growing economic pressure and increasing fluctuations in the quality of fuel, innovative and sustainable solutions for reducing costs whilst increasing efficiency are much sought after. Devising such solutions requires a highly developed level of expertise in process engineering as well as intelligent control and regulation of the incineration processes.

More than 150 incineration lines

SAR Process and Environmental Technology is the market leader in the field of combustion control systems for waste treatment plants, biomass and refuse-derived fuel-fired power plants.

To date more than 150 incineration lines in all size classes have been automated and thus optimised using the patented SAR combustion control system SAR-CCS.

More than 20 years of experience

Our employees can draw on more than twenty years of experience in the optimisation of thermal waste treatment plants. Generally, original equipment manufacturers (OEMs) only know their own products. By contrast, SAR has now gained familiarity with plants produced by all well-known OEMs and has modified, expanded, and optimised these and been involved in the construction of new plants.

A holistic approach

We know that in designing and optimising incineration plants one needs to look beyond an optimally functioning control and regulation system. Instead we consider the whole of the functional unit - and that includes the process engineering design, the sensor / actuator technology and the hydraulics. Only if these subsystems are perfectly matched to one another can you have an optimally functioning complete system.

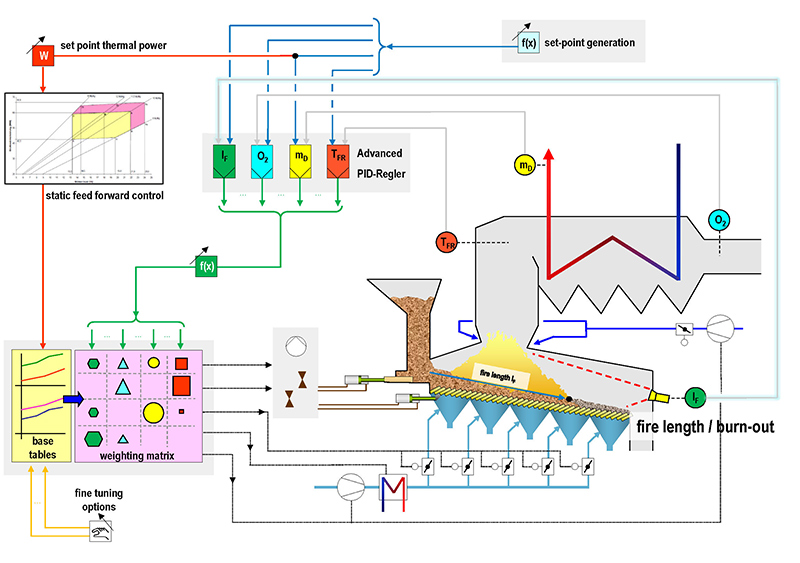

SAR fire length control

Efficiency of energy and resources is one of the central issues for the future. This is one of the reasons why we, as a company, have decided to focus on this at this early stage. In this we have benefited from our many years of experience in process control technology and process engineering for thermal power plants.

Thanks to our close contacts with universities and research institutions (e.g. EFRE, VOKOS), we have been able to use our expertise and innovative technologies to generate new practical applications: the latest development is the SAR fire length control system. This system can be used as an add-on to the SAR-If the operator subsequently switches to an alternative management system, the SAR-CCS is coupled to the new system as an autarchic system, and the only adjustment required is to the interface, if necessary. No changes to the combustion control system are necessary. or as a stand-alone.

The SAR fire length control system makes it possible to set a defined burn time for the combustion grate. Whether the fire burns for too long or too short a time, both constitute undesirable operating conditions. These operating conditions can be safely avoided using SAR's in-house development. For more information please take a look at our brochure at the bottom.

Economic potential

In addition to the environmental improvements, use of the SAR-CCS brings considerable economic potential. More even burning means greater effectiveness in incineration and steam generation and thus an improved performance. Constant controlled operation of the incineration process often makes it possible to operate the steam generator more closely to the way that was planned in the design.

Product and service range

- Consultancy for operators, plant manufacturers and engineering or planning offices regarding the sensor technology, actuator technology and regulation systems to be used

- Process analyses, mechanical, electrical and process engineering inventories

- Independent expert opinions on plant operation

- Drawing up of tender documents

- Basic and detail engineering of complete systems for combustion control

- Commissioning (international)

- After sales service and maintenance online / offline, on-call service 24/7

- Carrying out, supervision and documentation of trial runs, measurement campaigns or similar

System

Our solutions are based on hard and software suitable for use in power plants and are compatible with all standard management and control systems, or can even be integrated into existing management systems, which is often not possible with artificial neural networks and fuzzy logic, for example. The use of standardised interfaces means that they can also be combined with plants in operation without affecting the operation of the plant.

If SAR-CCS is supplied as a so-called external system, the operator is investing in future-proofing. In this case, the automation station with the CCS-logic is supplied in a control cabinet, including an industrial computer for operation and other equipment. An exchange of signals with the existing process control system is built-in.

If the operator subsequently switches to an alternative management system, the SAR-CCS is coupled to the new system as an autarchic system, and the only adjustment required is to the interface, if necessary. No changes to the combustion control system are necessary.

How high is the potential for optimisation?

If a plant operator is thinking about changing the combustion control system, the question of what results and improvements can be expected compared to the status quo always arises. It is a question that makes perfect sense, because this is a decision that will have not inconsiderable consequences.

Until the state of the plant is known, no reliable response to the question can be given. There are too many factors which affect the results. Only an on-site inventory, conducted over several days, including a comprehensive analysis of operational data, puts us in a position to make reliable statements.

For example, recommendations to increase the redistribution of primary and secondary air make no sense if the induced draught fan is already working to maximum capacity. This - tried and tested - procedure means that both customers and SAR can feel confident in the realistic assessment of the available potential for optimisation and the results that you can expect to achieve.

Bold and grandiose promises may sound very tempting and encourage you to buy, but may be followed by disillusionment far sooner than either party would wish once the existing framework conditions have been examined more closely.